Muhammad Wakil Shahzad

KAUST, Saudi Arabia

Title: Membrane & Distillation Processes Integration to Achieve Maximum Recovery

Biography

Biography: Muhammad Wakil Shahzad

Abstract

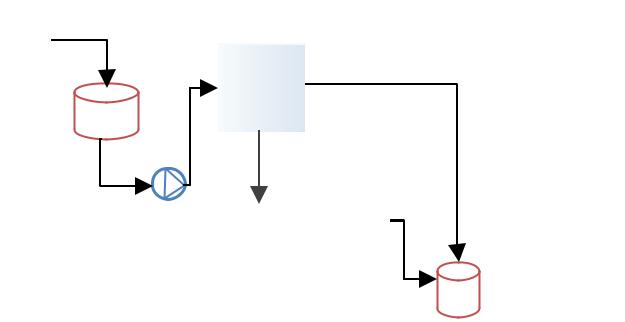

The economics of seawater desalination processes has been continuously improving because of desalination market expansion. Lower operating cost has been achieved by efficient operation strategies and better recoveries and the capital investment dropped many folds due to competent system designs and material development. Presently, reverse osmosis (RO) processes are leading in global desalination with 53% share followed by thermally driven technologies 33%, but in GCC their shares are 42% and 56% respectively due to severe feed water quality. In RO processes, intake, pretreatment and brine disposal cost 25% of total desalination cost at 40-45% recovery. We presented a tri-hybrid system to enhance recovery from RO retentate up to 85%. The proposed hybrid desalination cycle consist of two major systems, RO process and multi-evaporator adsorption system (ME-AD). They are arranged in series for maximum recovery from pre-treated feed. The conditioned brine leaving from RO system supplied to proposed multi-evaporator adsorption cycle driven by low temperature heat source such as solar energy or industrial waste heat. Detailed mathematical model of overall system (from one to four-evaporator adsorption cycle) is developed and simulation has been conducted in FORTRAN. The final brine reject concentration from tri-hybrid cycle can be increased from 166ppt to 222ppt if RO retentate concentration varies from 45ppt to 60ppt. The proposed tri-hybrid cycle is the highest recovery, 85%, and lowest specific water cost, 2.20 kWh/m3, reported in the literature up till now.The detailed process schematic of hybrid system is shown in Figure 1.

Figure 1: Membrane & thermal distillation hybrid processes flow schematic.