Adolfo Iulianelli

Institute on Membrane Technology of the Italian National Research Council, Italy

Title: Membrane technology for H2 separation

Biography

Biography: Adolfo Iulianelli

Abstract

Nowadays, gas separation technologies play an important role at industrial level in a large number of chemical applications. Among them, it is worth of noting the pressure swing adsorption, temperature swing adsorption, liquid absorption and stripping, cryogenic distillation and, as emerging technology, the membrane gas separation (MGS). In most of cases, they compete each other for the same application, whereas for high product purity requirements, a combination of them should be requested. Nevertheless, the recovery and desired purity requirements and the scale operation constitute the main variables for the selection of a separation process. The operational and economic benefits and drawbacks due to the utilization of MGS technology over other gas separation processes have been largely reviewed and a growing progress has been observed in this field. Moreover, in recent years, membrane engineering has driven to significant innovations in products and processes, making membrane technologies as a valid alternative to conventional operations. Meanwhile, the application of membrane technology in the viewpoint of the Process Intensification Strategy has made possible relevant benefits in terms of high energy saving, better raw material exploitation, lower waste generation and dramatic reduction of equipment size. Among a number of potential applications in chemical processes, such polymeric membranes are particularly used in H2/N2 separation (ammonia synthesis process) and hydrogen recovery in refineries. However, in the last years also inorganic membrane technology has received a great attention, particularly for H2 separation from industrial gaseous streams via Pd-based membranes. Here an application of thermal treated PEEK-WC and PLA membranes for separating H2 from other gases of interest is presented. Furthermore, a comparison with the utilization of composite Pd-based MGS technology is given, consequently pointing out the advantages and disadvantages of both applications.

Image

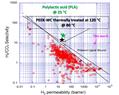

Figure 1. Permeation characteristics of PLA membranes over Robeson plot - H2/CO2 selectivity vs H2 permeability upper-bound.

Publications

- Iulianelli A, Alavi M, Bagnato G, Liguori S, Wilcox J, Rahimpour MR, Eslamlouyan R, Anzelmo B, Basile A (2016) Supported Pd-Au membrane reactor for hydrogen production: membrane preparation, characterization and testing. Molecules 21:581-594.

- Liguori S, Iulianelli A, Dalena F, Pinacci P, Drago F, Broglia M, Huang Y, Basile A (2014) Performance and long-term stability of Pd/PSS and Pd/Al2O3 for hydrogen separation. Membranes 4:143-162.

- Briceño K, Montané D, Garcia-Valls R, Iulianelli A, Basile A (2012) Fabrication variables affecting the structure and properties of supported carbon molecular sieve membranes for hydrogen separation. Journal of Membrane Science 415-416:288-297.

- Iulianelli A, Basile A, Li H, Van Den Brink RW (2011) Inorganic membranes for pre-combustion carbon dioxide (CO2) capture, in Advanced membrane science and technology for sustainable energy and environmental applications. Woodhead Publishing Series in Energy – Cornwall (UK), Ch. 7, pp 184-213.

5. Iulianelli A, Liguori S, Morrone P, Basile A (2012) Membrane and membrane reactor technologies for COx purification of gaseous streams. Nova Science Publishers, New York (USA).